Tests on filled rigid packaging - ASTM D5094

ASTM D5094 is a standard developed by the American Society for Testing and Materials (ASTM) that describes a test method for determining the integrity of a container closure using a vacuum chamber. This method is used to evaluate the tightness of caps, lids or other types of closures on containers such as bottles, flasks, jars, etc…

As a laboratory, we are well aware of the importance of simulating transport conditions on packaging. We are fully conversant with testing protocols and guide companies through the implementation of these processes.

Control Sensei offers you the peace of mind of knowing that all your needs will be met. We are in constant communication throughout the testing process. Where packaging does not meet requirements, we help you find solutions.

How the method works

The ASTM D5094 test describes 2 test methods:

- Method A

- Method B

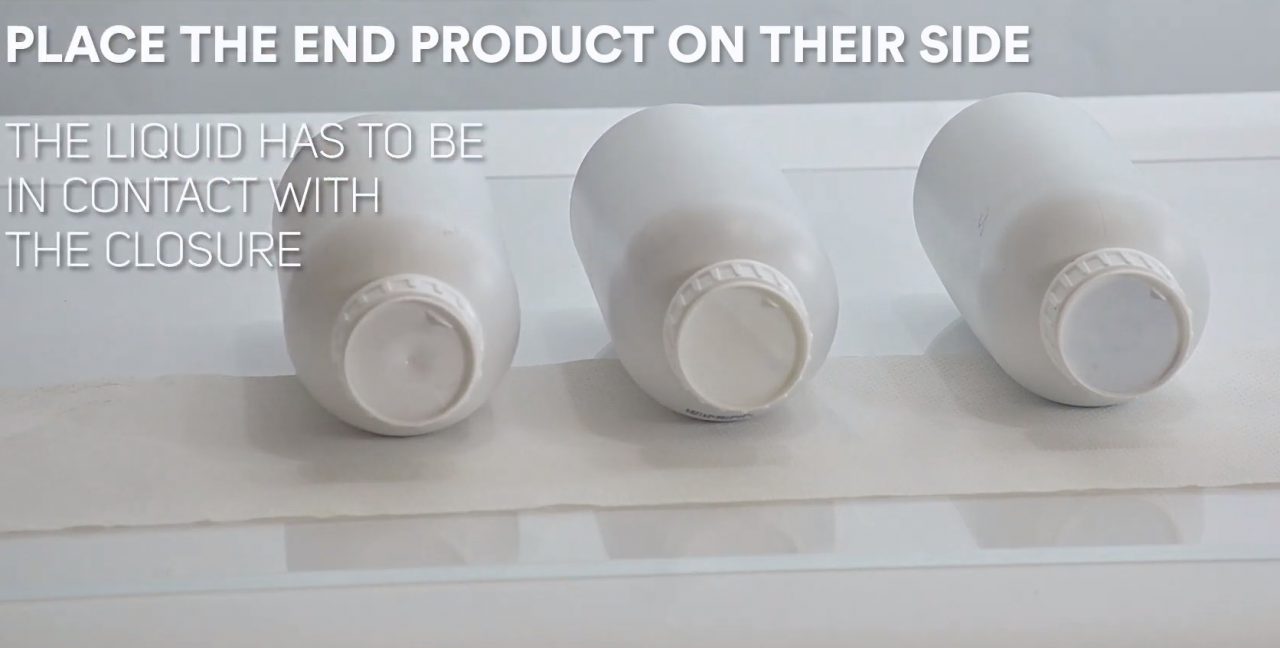

In this test method you will not need a vacuum chamber. The bottles/flasks or rigid packaging are laid on their side on an absorbent support, so that the liquid product is in contact with the cap.

We then wait 24 hours to see if any liquid has leaked onto the absorbent support.

If liquid has leaked onto the support, there is a leak.

This method is not suitable for large-scale production, as you run the risk of having problems with your 24-hour production schedule if a leak is detected…

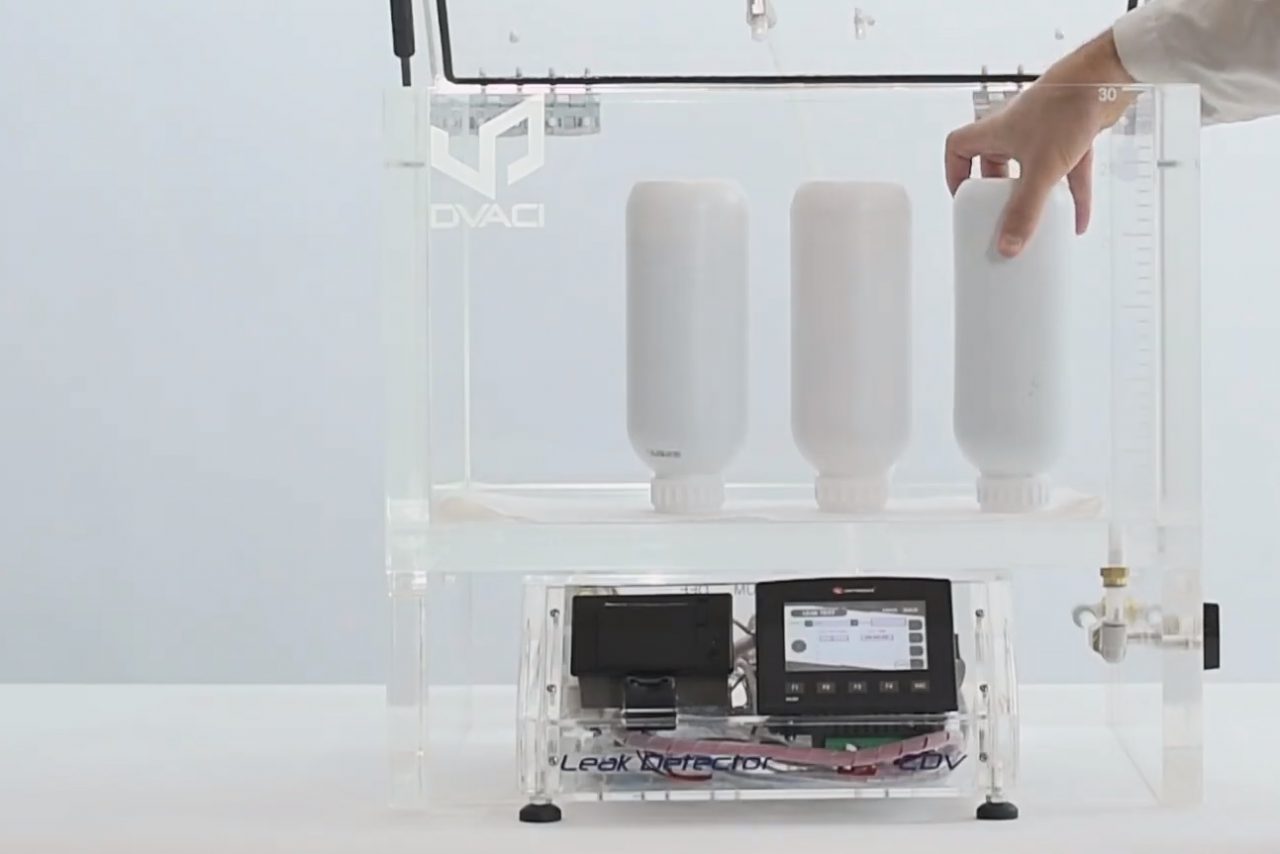

In this method we will use vacuum to speed up the test principle. The principle is the same: the samples lie on their side in a vacuum chamber and an absorbent medium is placed underneath.

The packaging is subjected to a vacuum and the residual volume of air contained in the packaging presses against the liquid, which in turn presses against the sealing element… so if there is a leak, the liquid flows onto the absorbent media.

The vacuum level is -340 mbar (-10 inHg) and must be maintained for at least 10 minutes.

Once the test is complete, simply check the absorbent media to see if any liquid has leaked out. If the media is intact, there is no leak.

ASTM D5094 tests apply to the following products:

- Industrial liquids

- Hazardous and non-hazardous liquids

- Rigid containers

- Beverages (non-carbonated)

- Perfume bottle / Fragrance

- Liquid cosmetics in bottles or flasks

- Pharmaceuticals

- Chemical products packed in rigid containers

- Personal care, health & hygiene

- Domestic cleaning

Our solution is tailored to your needs

Our vacuum chambers are hermetically sealed, so you can maintain a vacuum for as long as you like and carry out ASTM D5094 tests.

Our test programmes are designed to make test execution easy. The input screen allows you to enter the vacuum setpoint and the test time.

Other test methods

- ASTM D3078 – Immersion tests on flexible packaging

- ASTM D4991 – Tests on empty rigid packaging.

- ASTM D5094 – Tests on filled rigid packaging.

- ASTM D6653 – Altitude simulation on packaging

- ASTM F2096 – Internal pressurisation tests for packaging

- ISO 8871-5 annexe D – Dye penetration tests on medical packaging

- DIN EN 1779 – Non-destructive testing of flexible packaging