We carry out all the tests on your packaging for you

Immersion tests following ASTM D3078

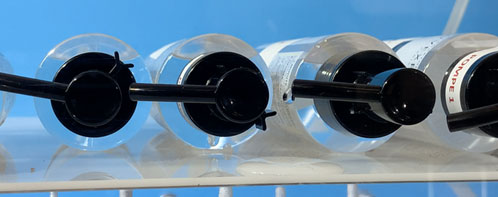

We can perform immersion tests to ASTM D3078 in our chambers.

The sample is immersed in a water bath. A vacuum is created in the chamber. Leaks are observed by the emission of bubbles at the leak.

Transport/Altitude simulation in accordance with ASTM D6653

We can also carry out simulations of behaviour at altitude in accordance with ASTM D6653.

Our chambers are equipped with specific programmes that convert differences in altitude into differences in pressure.

Dry tests on packaging containing liquid

For packaging containing liquids, the leak detection technique is different because the liquid leak can be observed visually if it is present on the packaging being tested.

This test technique involves laying the packaging containing the liquid on its side to bring the liquid into direct contact with the sealing element to be tested: cap, pump, stopper, etc.

Once in this position, the vacuum is created and the air contained in the packaging above the liquid increases in volume and presses against the liquid. As the liquid is incomprehensible, it will apply the same stress to the sealing element. This stress can cause a leak if the seal is not perfect.

Most of the time, the packaging is placed on an absorbent support so that the leak can be observed.

Book your laboratory test slot

You can contact us directly by e-mail: contact@control-sensei.com